Plasma filter: integrated technology for air purification

Cooking is a great pleasure, but what about the odors and smoke that result from it? The solutions used in the kitchen are the exhaust hood to expel air outside or the filtering hood. However, the exhaust hood, in addition to odors, extracts the warm air from the kitchen during winter and cool air during summer, thereby increasing heating and cooling costs. The filtering hood with activated carbon odor filters has limited efficiency in eliminating odors, and the maintenance costs are significant because the odor filters must be frequently replaced.

Now, all of this has a solution thanks to GALVAMET plasma technology filtering hoods

Efficiency in odor reduction up to 95%

What is Plasma?

It’s an ionized gas consisting of an electrically neutral mixture of electrons and ions.

How is Plasma created?

It is obtained by providing the molecules of a gas, at a given pressure, with sufficient thermal energy to dissociate the molecules and ionize the atoms and molecules of the gas itself.

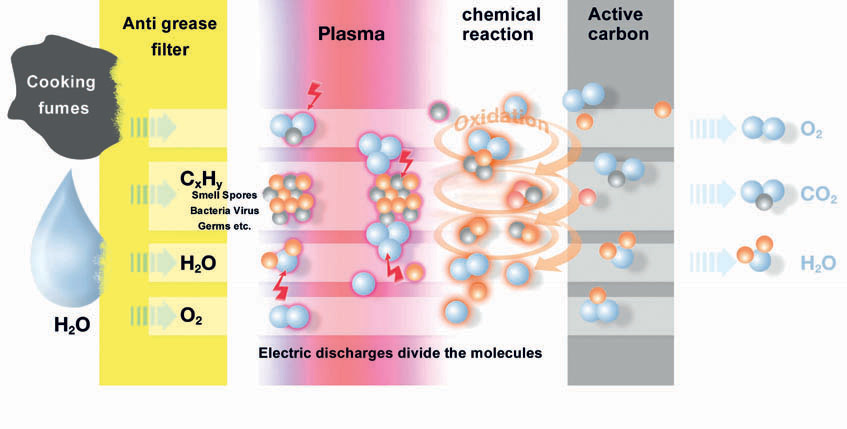

How does the Plasma filter work in a hood?

Odor molecules are deactivated, and viruses, microbes, spores, and bacteria are also eliminated. Exiting the Plasma filter, there will be only oxygen, carbon dioxide, and water vapor. Initially, the grease in the cooking fumes is captured by grease filters, the filtered air then enters the Plasma filter and is oxidized through “cold combustion.” Molecules, such as germs and odors, are decomposed at the molecular level.

Oxygen (O2), Carbon Dioxide (CO2), and Water Vapor (H2O) = PURE AIR.

The Plasma filter consumes only a few watts of electricity and requires no maintenance.

Advantages of a recycling hood with Plasma technology

Vs.

Exhaust hood with ducts

Aesthetic advantage

There are no longer any external air expulsion chimneys.

Installation cost savings

No more masonry work will be needed for the passage of air expulsion ducts.

Energy cost savings

A kitchen hood removes and expels not only odors but also the warm air during winter and the cool air in summer present in the kitchen. This process leads to greater use of heating and air conditioning systems, resulting in a significant increase in annual energy costs.

Advantages of a recycling hood with Plasma technology

Vs.

Recycling hood with carbon filters

Odor elimination

95% efficiency in eliminating odors compared to only 50/60% of a standard filtering hood with activated carbon odor filters.

Virus elimination

99% is the capability of Plasma filters to eliminate viruses, spores, bacteria, germs, etc., present in the kitchen air, compared to 0% of a standard filtering hood with activated carbon odor filters.

Durability

The lifespan of Plasma filters is 10 years without the need for maintenance or replacement; conversely, in a standard filtering hood with activated carbon odor filters, they must be replaced every 3/4 months. Therefore, the savings of a hood with a Plasma filter are evident.

Efficiency The efficiency of the Plasma filter in eliminating odors remains high for many years. On the other hand, the efficiency of a standard activated carbon filter declines very quickly (already after 3/4 cooking sessions).

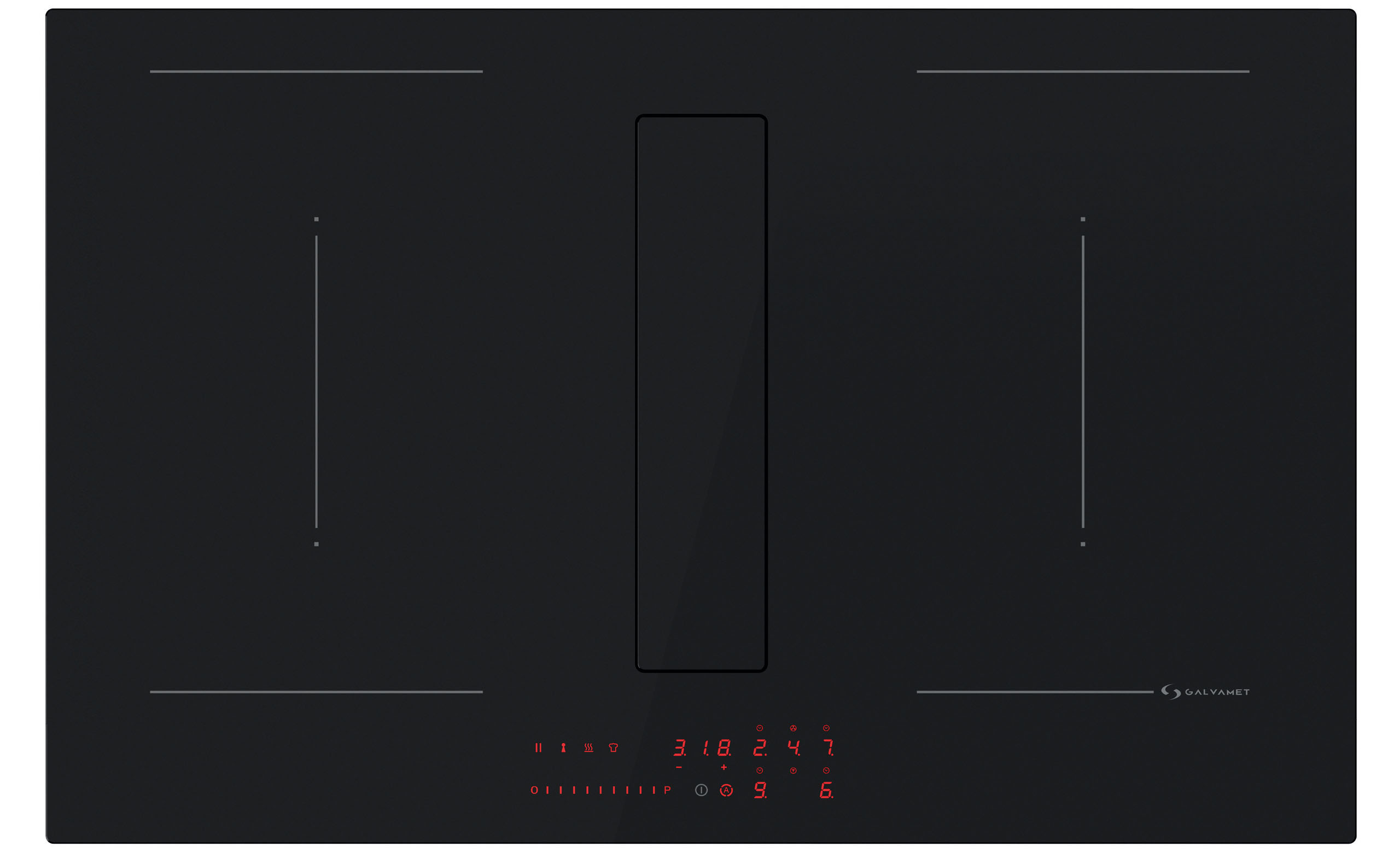

Models with Plasma technology

Subscribe to the newsletter

Don’t miss any news about our products and company, sign up for our newsletter!